Rochester Structural has a top notch structural steel detailing department located within our 60,000 sq. ft. facility. RS uses advanced 3D modeling software “Tekla Structures” with an extensive library of steel shapes to produce shop drawings and erection plans. RS can produce shop drawings for everything we fabricate.

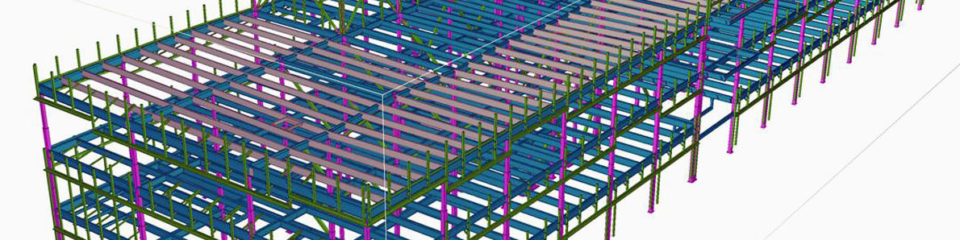

RS employs two full-time detailers to develop shop drawings generated from structural and/or architectural drawings produced by the customer. RS takes this information and inputs it into our modeling software to create a 3 dimensional model drawn to scale. RS is able to identify and coordinate with other trades using the 3D capabilities such as BIM Modeling, saving the customer time and money by bringing interferences related to the steel components to the design team's attention, often times with suggestions for a fix before the fabrication and erection stage.

Every piece of material whether a beam, column, plate or a piece of angle has a specific drawing created for fabrication. These are what we call fabrication drawings. Fabrication drawings at RS consists of two types: assembly drawings and part drawings. An assembly is a drawing that has all parts that are required to fabricate a column or beam in its entirety so that it will be considered a finished part. This drawing includes an extensive bill of materials on every drawing. A single part drawing is an individual drawing for each clip, plate, channel, etc. to make up an assembly drawing.

Tekla Structures is capable of downloading CNC files for each drawing directly to our CNC machines. This process eliminates each machine operator programming holes and cut lengths. This eliminates mistakes made in programming and increases turnaround time.

The last step of the shop drawing process is to create erection drawings. Erection drawings are drawings that are used to erect the structure. This set of drawings consist of anchor bolt plans, floor plans, roof plans, building elevations and details. Erection drawings have all the necessary information required to erect each specific job. (ie. anchor bolt locations, specific beam and column placement, and specific welding or bolting information)